Your added value of confection⁺ with Püplichhuisen

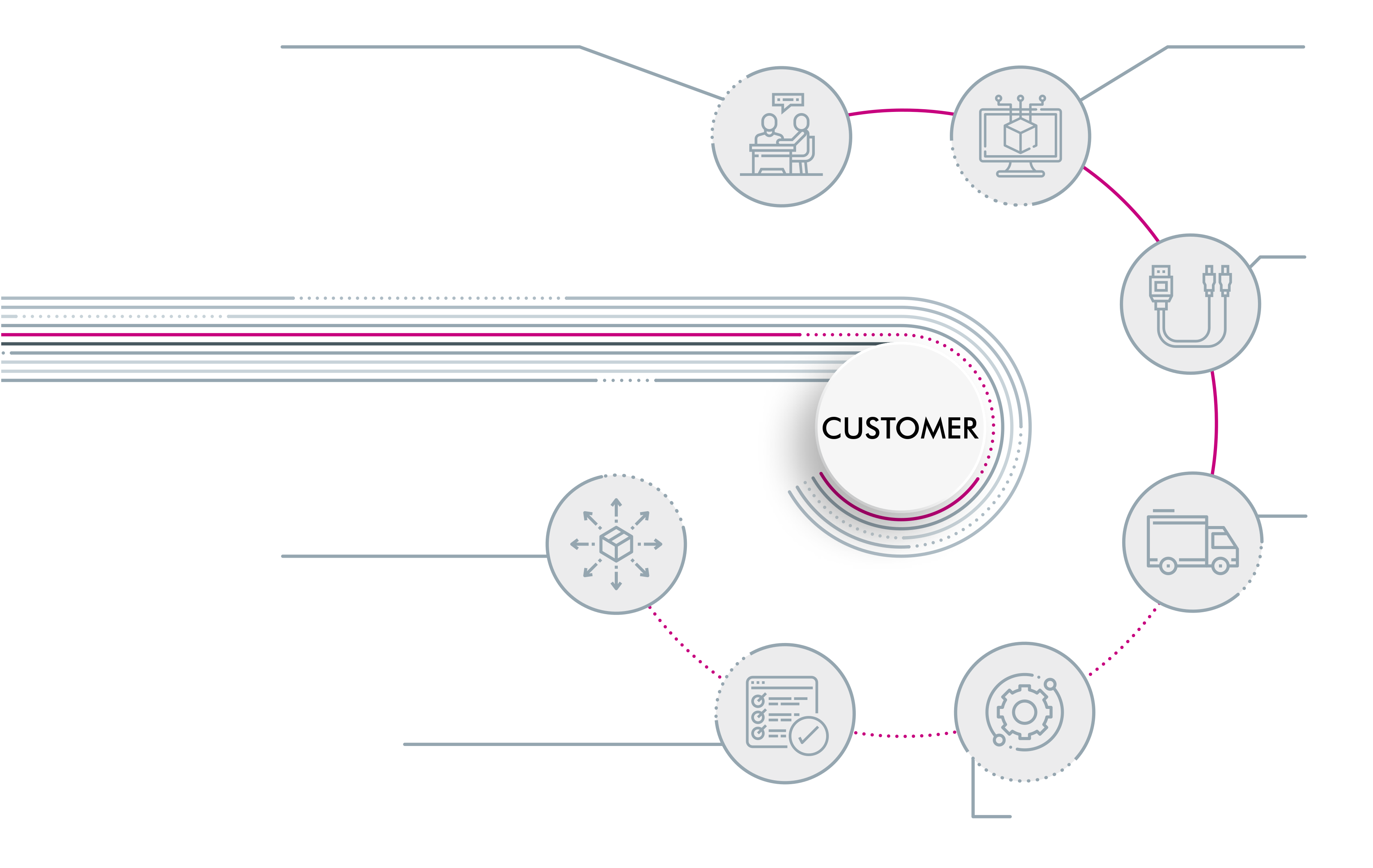

Individual advice from your personal contact

Our technical sales department provides holistic support for your project, on site if required: from conception through all production processes to distribution. As a result, you receive individual solutions tailored to your needs.

Optimized overall costs through reduced interfaces

We take over purchasing and service management in the areas of administration, procurement, production and logistics for you. This saves you time and costs in coordinating your project and conserves your capacities.

Production sites

With our three production sites in Duisburg, Sömmerda and Dzierzoniów (PL), we guarantee efficient and cost-optimized production of your individual products.

Hand in hand: distribution & cable assembly

The distribution area and the cable assembly of Karl Püplichhuisen GmbH & Co. KG share valuable resources. With the help of the existing structures, you benefit from ongoing material stocking and availability, as well as a fast flow of information.

40 years of experience in cable assembly

In Püplichhuisen you will find a long-term and reliable partner at your side. With our expertise, we are available to you as a trustworthy contact partner in all matters of cable assembly and distribution.

Our services

Application advice

What challenges are you facing? In a personal meeting, we analyze your application with you and advise you on technical, production-optimized and commercial solution options.

Design

Benefit from our expertise in wire harness design as well as in consulting specific interfaces in the field of metal and plastic components.

Sample service

Does our solution meet your expectations? A wire harness is largely manufactured manually despite a large number of automatic processes. Therefore, we are happy to produce your special release sample or prototypes in advance for coordination.

Procurement / Material Management

How can your complex product be realized? Trust in our worldwide network: Due to our distribution experience and long-standing manufacturer contacts in the field of electromechanics, we realize the procurement and warehousing of your components for you and are able to advise you regarding reasonable alternatives as well as allocation management.

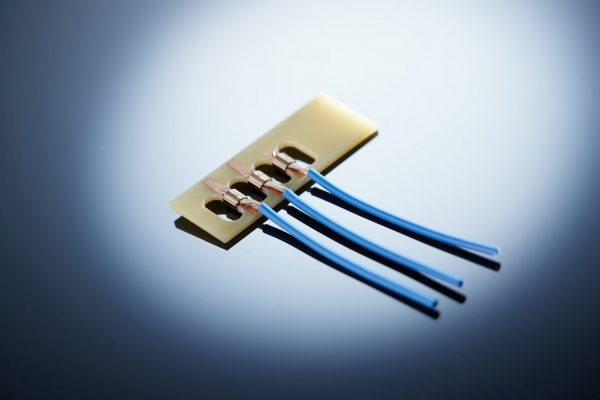

Production

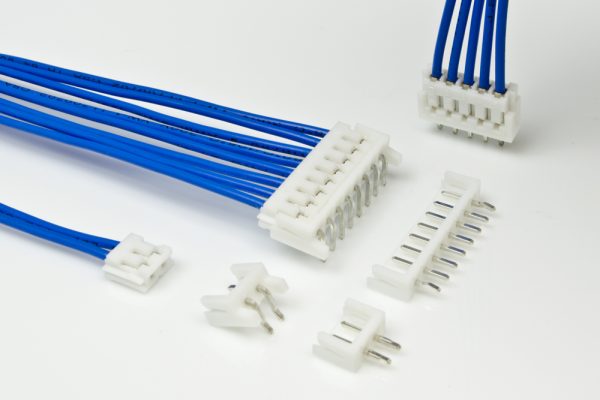

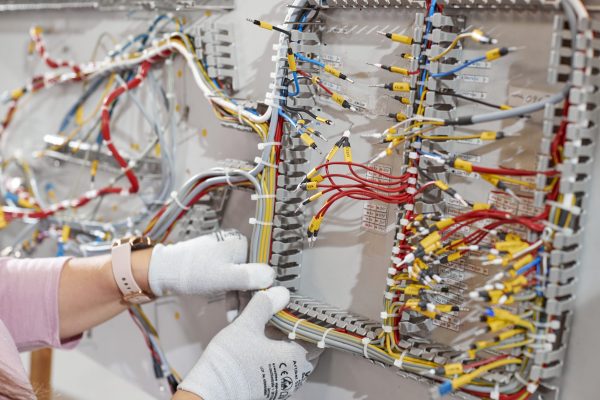

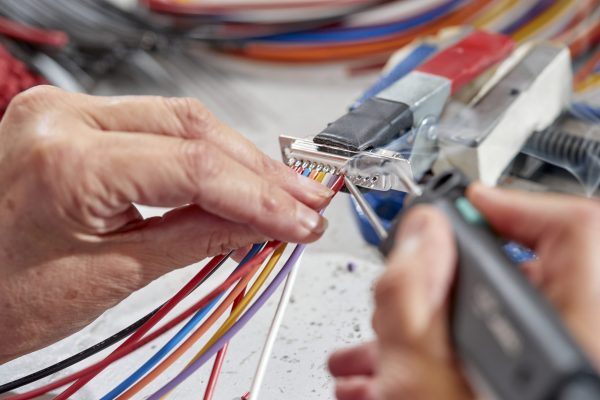

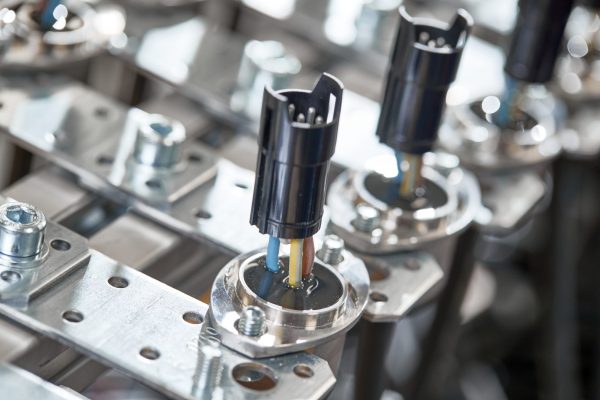

What technology do you need? With our broad spectrum in the production of wire harnesses and assemblies, we offer you manual assembly, semi-automatic production as well as full automation. In doing so, we combine the following techniques under one roof:

■ Crimp technology

■ Splicing technology

■ Shrink technology

■ Soldering technology

■ Pressing technology

■ Assembly technology

■ Marking technology

■ Potting 1K / 2K

■ Low-pressure casting (HotMelt)

Translated with www.DeepL.com/Translator (free version)

Quality assurance / certifications

■ DIN EN ISO 9001:2015

■ DIN EN ISO 14001:2015

■ UL Wiring Harness E-File E317941

■ UL Processed Wire E-File E338687

■ Pull-off test DIN EN 60352-2

■ Micrograph laboratory

■ 100 % testing (optical / electrical)

■ Initial sample test report

Packing & Logistics

■ AEO certified

■ Customized packaging

■ Individual printing / labeling